Recognizing the Fundamentals of Pipeline Welding Assessment: Crucial Factors for Examining Weld Quality and Preventing Failures

In the realm of pipeline welding inspection, the stakes are indisputably high, necessitating a thorough understanding of fundamental principles to make sure weld top quality and minimize failure threats. Various vital factors enter into play, consisting of the selection of ideal materials, the application of innovative assessment methods, and the acknowledgment of widespread welding flaws. Additionally, adherence to regulatory criteria plays a pivotal role in preserving system honesty. Yet, the intricacies fundamental in these processes elevate important concerns concerning finest techniques and emerging technologies that might redefine assessment methods-- concerns that necessitate additional expedition.

Importance of Weld High Quality

The honesty of a pipeline is basically reliant on the quality of its welds, making weld top quality an important consider making sure efficient and risk-free procedure. A pipeline weld works as a joint factor where products are signed up with, and any type of shortages around can bring about substantial structural weak points. Poor bonded high quality can lead to leakages, ruptures, and devastating failings, posturing significant safety and security threats and ecological dangers.

Several factors add to the quality of a weld, including the choice of welding process, the abilities of the welder, and the conditions under which the welding is carried out - Pipeline Welding Inspection. Poor prep work, improper warmth input, and contamination can jeopardize weld integrity, leading to issues such as porosity, insufficient fusion, or fractures. For that reason, rigid high quality control measures must be carried out throughout the welding process to minimize these dangers

Additionally, the long-lasting efficiency of a pipeline is greatly affected by the toughness of its welds. Premium welds not only boost the general strength of the pipe but also prolong its life span, lowering the demand for costly fixings and downtime. Hence, ensuring exceptional weld high quality is extremely important in pipeline layout and maintenance techniques.

Key Assessment Methods

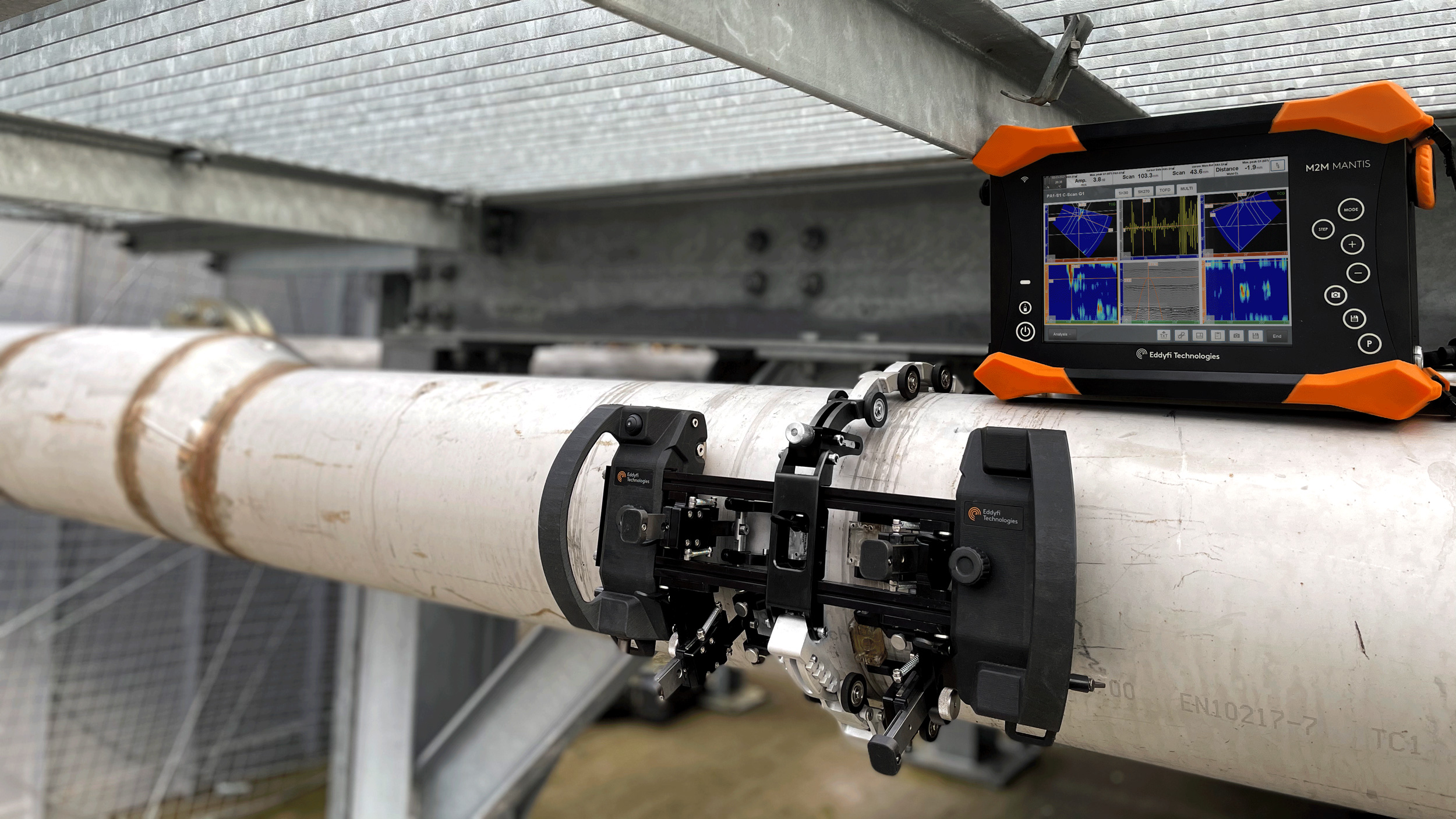

Ensuring weld quality requires the execution of effective examination strategies to determine possible flaws prior to they cause failings. Pipeline Welding Inspection. Amongst the most commonly utilized approaches are aesthetic examination, radiographic testing (RT), ultrasonic testing (UT), and magnetic bit screening (MT) Each strategy serves a distinctive purpose and is chosen based upon the specific requirements of the pipe project

Visual examination is the first line of protection, enabling assessors to examine surface area problems, positioning, and total handiwork. It is a cost-efficient and quick approach that can expose evident defects. Radiographic screening provides an in-depth view of interior weld integrity by utilizing X-rays or gamma rays to detect subsurface imperfections. This technique is particularly reliable for identifying gaps, additions, and fractures.

Ultrasonic testing employs high-frequency audio waves to examine the thickness and honesty of welds, making it perfect for detecting interior gaps. Magnetic particle testing is a dependable technique for determining surface and near-surface defects on ferromagnetic products by applying electromagnetic fields and great ferrous bits. By making use of these vital assessment techniques, pipeline welding inspectors can guarantee the best criteria are preserved, ultimately leading to more secure and extra reputable pipeline systems.

Typical Welding Flaws

In the realm of pipeline welding, recognizing common welding issues is vital for keeping architectural stability and safety and security. These problems can bring about catastrophic failures otherwise determined and addressed promptly. Among the most common defects are porosity, which happens when gas allures in the weld steel, developing gaps that compromise the joint. One more significant problem is lack of fusion, where the weld metal does not properly bond with the base material, endangering the joint's stamina.

Splits are likewise a vital concern, manifesting navigate to this website in various kinds such as warm fractures, cool splits, and root splits. Each kind poses one-of-a-kind difficulties and needs details examination techniques for detection. Undercut is another problem that can decrease the weld's cross-sectional area, causing tension concentration points, while slag addition occurs when non-metallic product comes to be trapped in the weld swimming pool, negatively influencing the mechanical buildings of the weld.

Additionally, incorrect bead shape can lead to uneven tension distribution. Acknowledging these common problems is important for welders and inspectors alike, as early detection and modification are vital to guaranteeing the durability and reliability of pipeline systems.

Materials and Their Influence

Picking the appropriate materials for pipeline additional resources welding significantly influences the general efficiency and dependability of the bonded joints. The selection of base steels, filler products, and layers plays a crucial function in determining the strength, rust resistance, and durability of the welds. For circumstances, carbon steel is typically made use of for its equilibrium of stamina and expense, yet it might be vulnerable to corrosion in specific environments, requiring making use of protective finishes or corrosion-resistant alloys.

Moreover, dissimilar steel welding needs cautious factor to consider of thermal expansion homes and potential galvanic deterioration. The compatibility of materials can considerably impact the microstructure of the weld, causing variations in mechanical buildings. For example, stainless-steel uses excellent rust resistance but may call for particular filler products to ensure an audio weld joint.

On top of that, the influence of temperature level and ecological conditions on product selection can not be ignored. High-strength steels may shed ductility at elevated temperatures, while low-temperature applications might require materials with improved durability. Ultimately, recognizing the implications of material options is vital for achieving optimal weld top quality and avoiding failures in pipeline systems.

Regulatory Requirements and Compliance

Regulatory standards and compliance play a critical role in pipeline welding, establishing the structure within which effective and risk-free methods are preserved. These standards are created by different organizations, including the American Culture of Mechanical Designers (ASME), the American Welding Culture (AWS), and the Pipe and Hazardous Products Safety And Security Management (PHMSA) Following these regulations ensures that welding This Site treatments satisfy the called for high quality and security benchmarks.

Compliance with regulative requirements is necessary not only for ensuring the integrity of the welds but also for protecting the atmosphere and public safety and security. Inspectors are charged with validating that welding operations abide by these standards via extensive evaluations of both the procedures and the last welds. This includes reviewing welder certifications, welding treatments, and the products used.

Failing to conform with established policies can cause significant consequences, including costly fixings, legal obligations, and disastrous failures. For that reason, organizations should integrate compliance into their operational techniques, cultivating a society of safety and security and quality. Regular training and audits are critical components in preserving adherence to these regulatory criteria, guaranteeing that all personnel are educated and furnished to maintain the greatest levels of pipe welding top quality.

Verdict

Finally, a thorough understanding of pipeline welding assessment is crucial for making sure weld high quality and protecting against failures. By using essential inspection strategies and acknowledging common welding flaws, inspectors can properly examine the integrity of welds. Factor to consider of material choice and adherence to regulatory requirements further improve the dependability and safety and security of pipe systems. Inevitably, these practices contribute to the prevention of leaks and disastrous failings, highlighting the vital significance of extensive inspection procedures in pipe building and maintenance.

In the world of pipe welding evaluation, the stakes are undoubtedly high, demanding a thorough understanding of basic concepts to make sure weld high quality and reduce failing dangers (Pipeline Welding Inspection).The integrity of a pipe is fundamentally dependent on the top quality of its welds, making weld quality a vital element in making sure efficient and risk-free procedure.Several variables add to the top quality of a weld, including the option of welding procedure, the abilities of the welder, and the conditions under which the welding is performed. Undercut is one more defect that can decrease the weld's cross-sectional area, leading to anxiety focus factors, while slag inclusion happens when non-metallic product becomes caught in the weld pool, adversely impacting the mechanical residential properties of the weld

In final thought, a thorough understanding of pipe welding evaluation is essential for ensuring weld high quality and stopping failings.